The T Series is 20 years old this autumn! To mark this momentous occasion we’re taking a retrospective look at the history of the T Series over the past two decades.

2002 T “Zero”

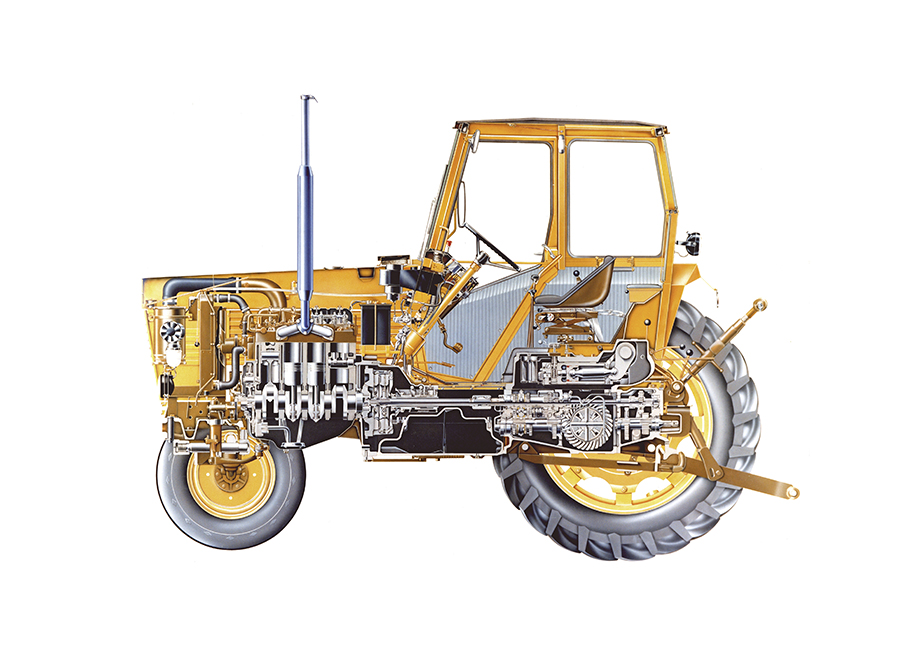

The T series was launched in September 2002 in Hungary, and production started a few weeks later in October. There was already a big demand for an update to Valtra’s six-cylinder mainline model series, as the 8000 Series was considered to be old-fashioned, especially when considering the rather dated appearance, and hydraulics.

Three years earlier Valtra’s S Series had already proven what an updated design could do. The new T series followed Valtra’s flagship with a design overhaul and new hydraulics. The long-awaited load-sensing hydraulics proved popular with fully electronic control of each spool valve. The newly designed hood, improved cab design, and control panels were a big step in the right direction. However, even with these innovations, the T Series remained essentially the same under the hood as the chassis was adopted directly from the 8000 series “long wheelbase” version, and the cab, frame, and construction remained from the old series.

The electronic control (often known as the “mixing console”) of hydraulics was considered too “technical” for many, so the old and familiar mechanical open centre hydraulics from the HiTech models was re-introduced in 2004.

T Series T2, 2009-2012

2007 T1 & T2 - the next steps

In 2007 the T Series was further upgraded to meet the emissions rating for Stage 3A – with the common-rail, 4-valve engines and the model markings changed to end with “1”. The load-sensing hydraulics strategy was also changed; now everything could be controlled from the armrest. At this time, the T series portfolio included the classic, HiTech and Advance models. These tractors still had a relatively short transmission and long, 160-litre chassis fuel tank made of steel. This was a favourite of forest drivers. However, on long field day an accompanying plastic tank was needed.

But there was more to come: Towards the end of 2007, a big product launch took place in Hämeenlinna, South Finland. The T Series boasted a totally new five-step powershift unit (Versu) as well as Valtra’s own CVT (constantly variable transmission). The much-anticipated new T Series model range was well received. Valtra dealers were particularly eager to receive the new T Series, although it took more than a year for production to get fully underway. Meanwhile, the Stage 3B solutions with SCR (systematic catalytic reduction) were already under development.

Valtra T Series T3, 2011

2012 T3 –intermediate model (Stage 3B)

The SCR was incorporated into third-generation T Series models with production starting in 2012. Although the launch went well, one criticism levelled at the T Series was its outward design, which some felt resembled previous models too closely. Ever one to listen to our customers, Valtra took the comments on board and implemented a facelift. Another issue was that the front lift was very popular in many countries, yet it was not well suited to the way the T Series was built at the time. The front axle was located directly under the engine to balance the weight over both driving axles. However, this proved problematic with large front implements, which made the front too heavy. Furthermore, the turning radius was not among the smallest on the market – wheel sizes having gotten bigger over the years.

2014 T4, A success!

In the Autumn of 2014, everything changed. Not only were the front and rear lift re-engineered, but just about everything in between was redesigned! The new design, new cab, and new chassis were all major improvements. The new 4th generation T Series was enthusiastically received by customers and dealers and received critical acclaim in the agricultural press. Until now, previous generations of the T series had not won any prizes, but the new T Series received many in several forums.

The T Series development did not end there. In 2017 Valtra launched the revolutionary SmartTouch user interface; a new control armrest and 9” touch screen. SmartTouch revolutionised the driving experience, further enhanced by Valtra Guide, the easiest-to-use automatic steering system on the market.

Valtra T Series T4, 2017

2021 T5. Today

Two years later, 2019, the engine was upgraded to meet the EU Stage V emission standards, and finally, the whole series moved to the fifth generation with the help of a new user interface. One big change, which is not visible to users but is extremely important, is the move to the RMI (repair and maintenance information) system. Originating from an EU directive, this move saw a complete change in the electronics structure of the T Series. At the same time, a new service tool was adopted which guarantees the service fit for each individual vehicle.

T series is like driving on air

Pneumatic front axle suspension had already been introduced towards the end of the 1990s for the Mega 8000 Series, and it was a natural selection for all T Series models. However, not all customers took advantage of this. Take-up rates for pneumatic front axle suspension in first-generation T Series models were something like 40%. This is low when compared to today’s 5th generation T Series where some 93 % are fitted with pneumatic front axle suspension.

Of course, various design improvements mean that today’s pneumatic suspension solution is very well integrated into the tractor, unlike the bulky construction available in earlier generations. Despite this design difference, the function has always been excellent, in any work and at any temperature. This highlights in particular how tractors (and especially the T Series) have developed over the years: More comfort, more efficiency –and (not forgetting) the overall design!

Valtra T Series T5, 2021

Valtra T Series models

You may also be interested in reading

Valtra tractor traffic between the UK Germany and Finland

70 years of colourful tractors

Get to know the 5th generation T Series